charpy impact test polymers|charpy impact testing procedure : mfg Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture . Resultado da s05e06 - Competence; s05e07 - Precious; s05e08 - Virtue; s05e09 - Scoundrels; s05e10 - House Counsel; s05e11 - Guardian; s05e12 - .

{plog:ftitle_list}

Mensagens para bodas de trigo Sinto o maior orgulho da nossa história. Parabéns para nós, que hoje celebramos nossas bodas de trigo. São três anos compartilhando muito .

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .Test methods used to measure Notched Izod Impact (or notch sensitivity) and Charpy Impact in plastics are: ASTM D256-10(2018): Plastics — Determination of Izod pendulum impact resistance; ISO 180:2019: Plastics — Determination .Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture .Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture .

The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at .This document specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined.ISO 179-1:2010 Plastics — Determination of Charpy impact properties Part 1: Non-instrumented impact test. Withdrawn (Edition 2, 2010) New version available: ISO 179-1:2023. Abstract. .1.1 This document specifies a method for determining Charpy impact properties of plastics from force-deflection diagrams. Different types of rod-shaped test specimens and test .

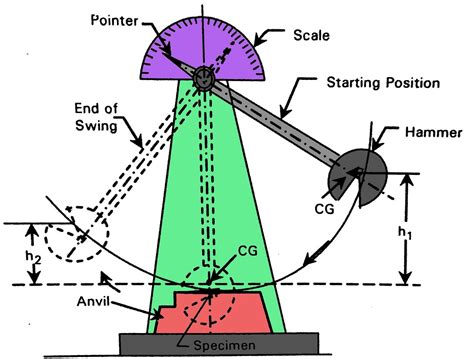

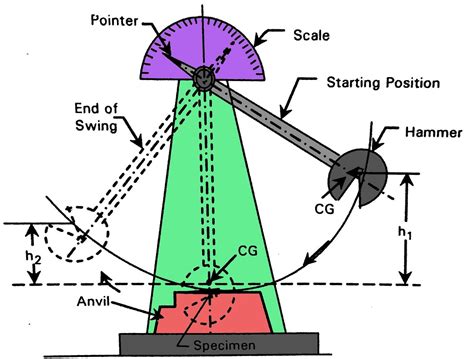

The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

charpy impact testing procedure

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. This test, on the contrary of Izod and . The test mostly adopted in order to evaluate the toughness of polymers under impact loading are the Charpy, theExplore Charpy Impact Testing, a reliable method for assessing material toughness. Learn how it works, key benefits, and how to interpret Charpy impact test results for industrial use. . If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials. Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . While most commonly used on metals, it is also used on polymers, ceramics and composites. .

Both methods characterize the impact strength of a material in very similar ways so that the results largely correlate. The Izod test method, in which the specimen is positioned vertically, is normally used in ASTM standards.; The Charpy impact test, which uses a three-point bending arrangement, is the preferred method in ISO standards.; Both methods are used to measure .CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values recorded can be used for quality

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool.The Charpy impact test is used to determine the impact toughness or impact strength of a certain specimen. The apparatus used are the Zwick Roel Charpy testing machine and a V-Notch Charpy type specimen. . also it showed that there was a great difference result for notched and un-notched condition for each polymers. Since the impact test gave .

The results obtained from the Charpy impact test for epoxy matrix composite reinforced with continuous and aligned mallow fibers, in percentages 0, 10, 20 and 30 vol% without treatment as well as 30 vol% with treatment, CP4 in Table 2, disclosed a good ability to absorb energy as compared to other polymer composites reinforced with NLFs [23].The Charpy and Izod tests, which were developed, cleared the path for impact testing of plastics. In 1900, the Charpy impact test was invented by Georges Augustin Albert Charpy. In the end, it was thought to be a very well-liked test for determining the relative toughness of materials. The thing that people enjoyed the most was how affordable . Charpy Impact Test of Polymer Composites with Epoxy Resin Reinforced Jute Fabric Download book PDF. Download book EPUB. José Gustavo de Almeida Machado 6, Juliana Peixoto Rufino Gazem de Carvalho 6, Anna Carolina Cerqueira Neves 6, Felipe Perissé Duarte Lopes 6, Sérgio .

In essence, the Charpy impact test is primarily used on metals while the Izod impact test can be used on both metals and plastics. So, if you are in search of a plastic impact tester, you should go for Izod. Many industries use Izod impact testing for plastics. Nonetheless, this does not mean that Charpy impact testing for plastics is not possible. Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics 1 This standard is issued under the Þxed designation D6110; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the .

charpy impact testing methods

Always unstable 5 (L/D) 10 15 Figure 5 Stability regions for the Charpy test 516 Impact Testing of Polymers 1.5r Figure 6 Stable crack growth plotted on an unstable crack basis 517 Fracture 1977, Volume 1 0 0.5 apparent 1.0 1.5 Figure 7 The effect of a plastic zone on unstable data 518 Impact Testing of Polymers Striker Specimen pwwvf Figure 8 .

Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. This test, on the contrary of Izod and . The test mostly adopted in order to evaluate the toughness of polymers under impact loading are the Charpy, the

Another very important factor, which influences the toughness, are notches as well as the shape of the notch [12, 13, 14].Cho et al. [15] and Allen et al. [16] investigated the impact strength with a Charpy impact test and found a drastic increase of impact strength with an increasing notch radius for PC.The addition of rubber particles to PC led to a lower increase in . Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead .Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.Charpy impact test piece: Plastics−Determination of Charpy impact properties: Charpy impact test piece: Each test piece has an indentation called a notch which is created in order to concentrate stress. There are two notch types: V-notch and U-notch. The test pieces used for edgewise impact are different from those used for flatwise impact.

ISO 179-1:2010 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined. Different test parameters are specified according to the type of material, the type of test specimen and the type of notch.

The ASTM D6110 Charpy Impact Resistance Test for Notched Specimens of Plastics is a test method for plastics.It is essential to the material science sector. It is especially so when evaluating and choosing plastic materials for different uses.1.1 This part of ISO 179 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined. . ISO 13802, Plastics — Verification of pendulum impact-testing machines — Charpy, Izod and tensile impact-testing; 3 Terms and definitions. The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load .

Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. This test, on the contrary of Izod and . The test mostly adopted in order to evaluate the toughness of polymers under impact loading are the Charpy, theFor this model, the impactor has 0.504 kg, this value being characteristic for Charpy test machine for polymers and the impact surface is plane. Its geometry is very close to that proposed in standards. . Holt J M 1990 Charpy Impact Test: Factors and Variables (Philadelphia: ASTM) [2] Francois D and Pinneau A 2002 From Charpy to present .

charpy impact test sample

charpy impact test formula

WEB14 de mai. de 2021 · Musica - “12” Letra/Voz - DEGE/ @degenoog | PEDRIN/ .

charpy impact test polymers|charpy impact testing procedure